Weight shift builds, another level of drift creativity?

Weight shift builds, another level of drift creativity?

7/1/25, 5:00 PM

Weight shift builds, another level of drift creativity?

Weight shift builds, another level of drift creativity?

I’ve been in the RC Drift hobby for about a year and half now and during this time I’ve focused on the weight shift builds, also known as “Load Transfer Systems” (LTS). “Weight shift” is what happens when the car transitions, as if in the middle of an “S” shaped road, and the weight of the car shifts from one side all of the way to the other side. Encouraging this weight shift, or transfer of load, can speed up the transition and make the chassis drop to the outside and snap into the slide.

Aside from how they physically look sliding and dragging the bumper, the appeal is how well a properly set up weight shift car can perform. Despite being a “far from ordinary” set up, it’s another level of being able to express your creativity with a chassis setup in an already extremely personalized hobby.

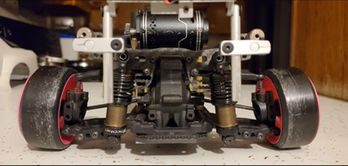

When most people hear or think of a weight shift (LTS) car they think of a high Center of Gravity (COG), which you do want. You can achieve a high COG by using a high battery mount, high motor mount, high esc mount, and high mount knuckles. That is typical for a chassis geared towards roll. However, the LTS setup also allows you to utilize and fine tune where the weight is being transferred. It can be transferred wherever you want to find more traction, transition speed, or style points. I’ve actually seen low battery set up cars perform and mimic one of my high mount weight shift setups perfectly just by using the other contributing factors for weight shift. Of course, a big factor is learning to adjust your driving style to the performance of a weight shift car.

The main thing to pay attention to in your alignment for a big body roll car is camber progression in the rear. Camber progression is how the contact patch of your rear tire is affected by the suspension stroke or travel. Some like their camber progression or gain to come through the car squatting. Some prefer it to progress through the body roll. Most of my set ups and most other setups I’ve noticed utilize standoffs or a higher mounted short rear link. That’s because it causes the lead rear tire to remain flat through the progression stroke, as opposed to excessive tire roll from the chassis rolling. This also can be countered with rear camber as it’ll flatten out through the stroke.

The next aspect some but not most consider is roll center. I tune my roll center with my suspension blocks. I set the upper link so that it meets the hub. Flipping suspension blocks and raising that contact point of the upper arm (or link) in turn lowers the roll center, induces roll, and stabilizes the chassis. The usual arrangement for a LTS is high COG, low roll center.

“Lever ratio” is an interesting setup modification I’ve discovered. The Lever ratio is the distance from inner suspension pin to shock mount, divided by distance from inner suspension pin to tire contact patch. With a weight shift build it’s considered ideal to have a higher lever ratio opposed to a lever ratio that’s closer to one. A ratio closer to one would be having the shock mounted as close to the hub carrier or tire contact as possible . This would potentially give the shock a stiffer action (also dependent on spring selection). A higher ratio or damper closer to the inner suspension pin, in a vertical orientation, will give more droop and spring action. Spring shock length, and suspension block are all dependent on chassis set up.

My chassis weighs about 1400 Grams. Another big factor for LTS is chassis weight placement. I generally try to keep the main deck as light as possible and keep the bigger items, the Electronic Speed Control (ESC), battery, and motor up high.

Damper Length and Spring Rates are also very important. The largest shock length I’ve found to work so far are the MST TR60 dampers. I use the TR series on everything and love them. My “go to” damper springs are the WUN compression springs, which always seem to work really well. They come in a 3 pack with different rates to test and tune with. I usually land on the yellow springs in the rear and red springs up front, but it’s also dependent on chassis weight, lever ratio, and damper length. I’ve heard that using either the front or the rear stock D-Like RER Hybrid springs work well. I’ve found so far that running a lighter oil has worked best. If the shock has a silicone oil o-ring, then I like using the Reve D 5wt. If it’s a mineral oil O-Ring, then I like the MST mineral oil the 5 or 10. I usually drill the stock pistons out to 1.2-1.5mm diameter and that seems to work pretty well for me.

I haven’t ever messed with any cantilever setups but I’ve played with my fair share of standard suspension geometry set ups. I’ve always used a traditional style shock configuration. I certainly don’t think using a mono-shock would have any negative effects. If anything, it might toss it a little harder due to the increased traction and transfer of weight.

I would like to test using a sway bar because I would like to see how they help reduce chassis roll while maintaining weight shift.

I’ve seen some LTS cars get up on 3 wheels and I think it looks great. My LTS builds don’t always get up on 3 wheels, but you can definitely see the front corner rise and the rear corner drop while it’s moving. Guys at the track always tell me “man I love watching your cars just heave in and out of transitions”.

I don’t set the ride height terribly high, it isn’t monster trucking. However, it’s not like stanced out low life scraper either. With the body on it, it looks normal and somewhat laid out, but when it’s in motion it comes alive. There is definitely a lot of droop. I adjust the preload (spring tension) rings on the dampers to how I like them to feel and then adjust the ride height using the shock cap length or rod piston shaft end length. I don’t adjust the ride height with preload and I try to keep my preload as little as possible. My current LTS car can drag the rear bumper if I toss it and get in throttle hard enough. I’d still consider that to be a moderate amount of roll. My current rig was one of my first successful LTS builds that I could start noticing the body roll and performance changes.

When a weight shift car is properly set up, it can actually be a comp weapon for big speed and angle tandems. The additional traction really is something that should be experienced at least once. It’s fast, fun, and looks so cool moving.

Currently, my main LTS car is my Shark, which started out just as a normal Shark on a Hydra deck, but I slowly convinced myself to set it up how I wanted to . I’m in the process of building another Yokomo YD/RD2 based LTS car as well. I’m also waiting for my Wrap-Up-Next (WUN) Travis2 to arrive.

If you’re going to tune a weight shift chassis, you’ve just got to commit. I recommend having one chassis that’s set up and works so you can have something functional while getting your weight shift car set up. It’s a process, but it can be very rewarding once it’s there. A weight shift car can work against you just as much as it can improve your RC drift experience. Seek advice, express yourself and enjoy the process along the way.